Hydraulics: Difference between revisions

No edit summary Tag: Reverted |

m (Reverted edits by Rmanwaring@gfnet.com (talk) to last revision by Grichards@gfnet.com) Tag: Rollback |

||

| Line 2: | Line 2: | ||

[[Category:Home]] | [[Category:Home]] | ||

---- | ---- | ||

{| align="right" style="width:10%;" cellpadding="7" | {| align="right" style="width:10%;" cellpadding="7" | ||

| [[Image:CFD1.png|800px|x800px|link=Outlet Configuration]] | | [[Image:CFD1.png|800px|x800px|link=Outlet Configuration]] | ||

Revision as of 19:41, 19 May 2023

|

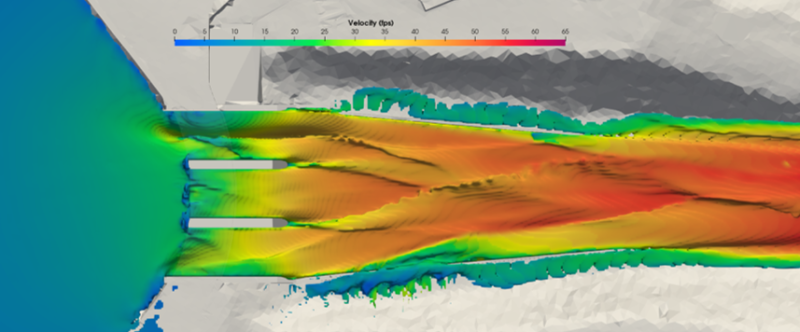

| Analysis of spillway hydraulics using Computational Fluid Dynamics (CFD). CFD can be used to model three-dimensional hydraulic conditions (such as the standing waves downstream of the control section in this picture) that are important in evaluating spillway capacity and the adequacy of spillway training walls. |

The hydraulic design of a dam includes a knowledge of the following foundational topics: pressurized and free-surface flow, uniform flow, gradually and rapidly varied flow, steady and unsteady flow, energy and momentum principles, energy losses, and cavitation. [1]

Types of Evaluations

- Hydraulic Performance of Spillways

- Hydraulic Performance of Outlet Works

- Dam Breach Inundation Analysis

- Spillway Integrity Analysis

- Erosion & Scour Mitigation

- Tailwater Modeling

Hydraulic Calculation Methods

Several calculation methods have been developed to represent various hydraulic flow conditions. Some of these methods are founded in theory, such as the Bernoulli Equation which represents the conservation of energy within a non-compressible fluid in motion. Others are empirical in nature. These types of equations are based on observations and experience as opposed to theoretical relationships. Hydraulic calculation methods include the following:

Types of Hydraulic Modeling

Hydraulic conditions are often quite complex and difficult to represent using simple mathematical routines. In these cases, numerical models and computer programs have been developed to solve these complex hydraulic computations. Selection of either a one-, two-, or three-dimensional hydraulic model is necessary depending on both the complexity of the flow conditions and the level of accuracy required of the model. Hydraulic modeling helps to attain a higher-optimized level of operation of the dam and reduce uncertainty.

“Maintaining the high efficiency of a spillway requires careful design of the spillway crest, the approach configuration, and the piers and abutments. For this reason, when design considerations require departure from established design data, model studies (or three-dimensional computer models) of the spillway system should be accomplished”. Physical model studies or three-dimensional Computational Fluid Dynamics (CFD) models are recommended to confirm any design that involves complex geometric considerations and/or large discharges and velocities. [1]

- One-Dimensional Hydraulic Models

- Two-Dimensional Hydraulic Models

- Three-Dimensional Hydraulic Models

- Physical Models

Best Practices Resources

![]() Technical Release 210-60: Earth Dams and Reservoirs, NRCS, 2019

Technical Release 210-60: Earth Dams and Reservoirs, NRCS, 2019

![]() Selecting and Accommodating Inflow Design Floods for Dams (FEMA P-94), FEMA, 2013

Selecting and Accommodating Inflow Design Floods for Dams (FEMA P-94), FEMA, 2013

![]() Hydraulic Design of Spillways (EM 1110-2-1603), USACE, 1992

Hydraulic Design of Spillways (EM 1110-2-1603), USACE, 1992

![]() Design of Small Dams, USBR, 1987

Design of Small Dams, USBR, 1987

![]() Hydraulic Design of Reservoir Outlet Works (EM 1110-2-1602), USACE, 1980

Hydraulic Design of Reservoir Outlet Works (EM 1110-2-1602), USACE, 1980

Trainings

![]() On-Demand Webinar: Hydraulics 101: Intro to Hydraulics for Dam Safety

On-Demand Webinar: Hydraulics 101: Intro to Hydraulics for Dam Safety

![]() On-Demand Webinar: Hydraulics 201 for Dam Safety

On-Demand Webinar: Hydraulics 201 for Dam Safety

![]() On-Demand Webinar: Inlet and Outlet Hydraulics for Spillways and Outlet Structures

On-Demand Webinar: Inlet and Outlet Hydraulics for Spillways and Outlet Structures

![]() On-Demand Webinar: Designing Spillways to Mitigate Failure Modes

On-Demand Webinar: Designing Spillways to Mitigate Failure Modes

![]() On-Demand Webinar: Introduction to Addressing Inadequate Conveyance Capacity at Dams

On-Demand Webinar: Introduction to Addressing Inadequate Conveyance Capacity at Dams

Citations:

Revision ID: 6812

Revision Date: 05/19/2023